(Source: Patria, as published by in 3dprint.com )- Finland’s First 3D Printed Aircraft Engine Part Takes to the Skies in Maiden Flight

One field that 3D printing technology has definitely made a major impact on over the last several years is aerospace – so much so, in fact, that the FAA is currently working to develop a plan on how to deal with the increased rate at which the industry is adopting 3D printing.

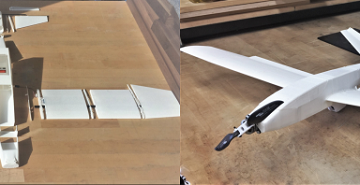

The technology is very useful in manufacturing aircraft, as it can reduce the weight of components, as well as producing parts with reduced complexitythat offer consistent quality and repeatable characteristics. These features can lower energy expenditures and cost, while also increasing aircraft performance, in the aerospace and defense industry, and a wide variety of aircraft, from drones to jets and rockets, now use 3D printed parts.

Many of these aircraft feature 3D printed engine parts, which can help reduce the total number of pieces that make up the component…which, again, helps with weight reduction. By using 3D printing technology to make the parts for an aircraft engine, companies can also see other benefits as well, including an increase in power and a decrease in fuel burn. (…)

Patria has long been involved in using modern manufacturing methods to fabricate and repair different parts and components for aircraft, and has spent more than two years working on the manufacturing process for a new 3D printed part. That hard work has finally paid off, as the country’s first 3D printed aircraft engine part, installed in the F/A-18 Hornet strike-fighter, recently went on its successful maiden flight. (…)

READ FULL ARTICLE >>> https://3dprint.com/201274/finland-3d-print-engine-part/

Photo >>>T 25 Sensor Housing – first 3D printed component in GE90 jet engine, ibid